industry

Mining & Aggregate

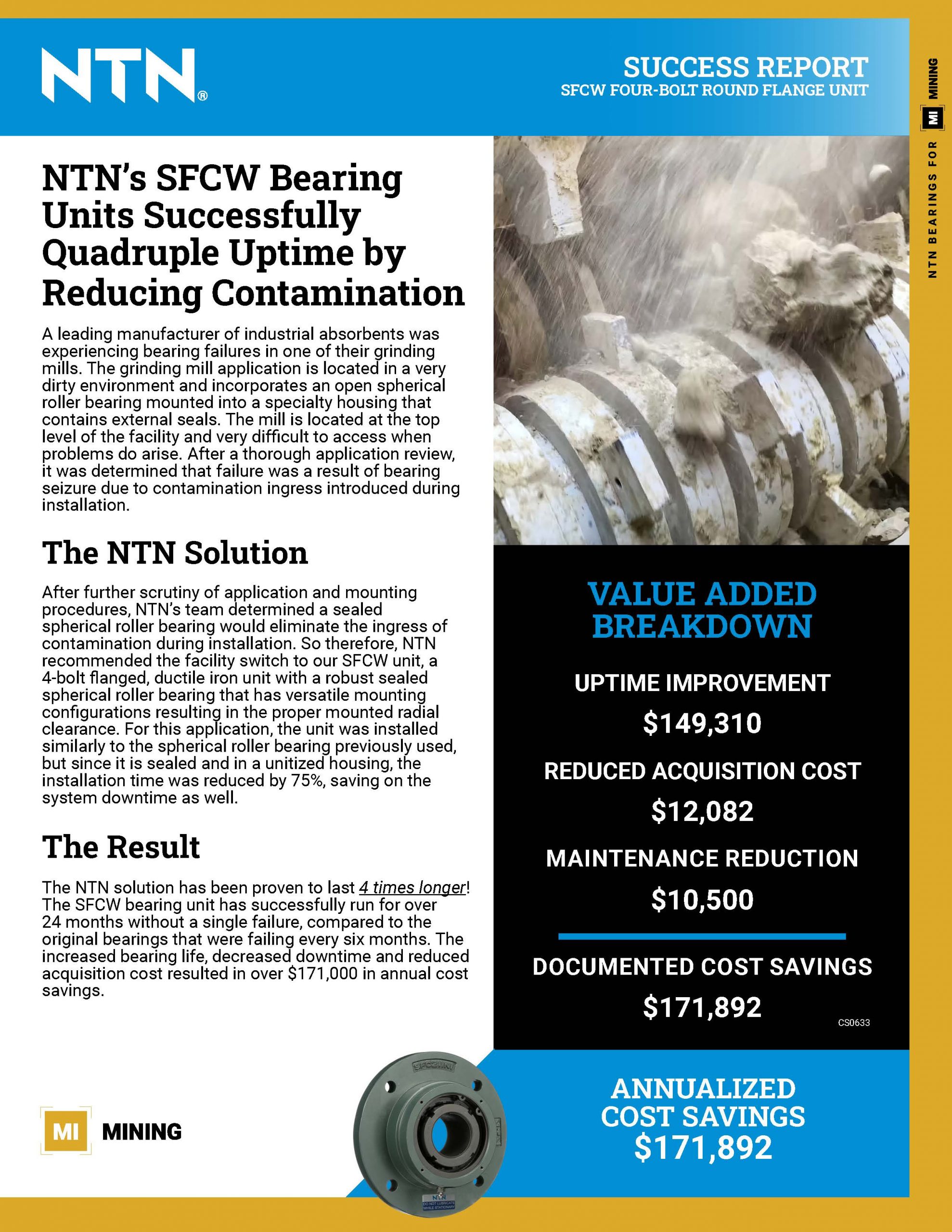

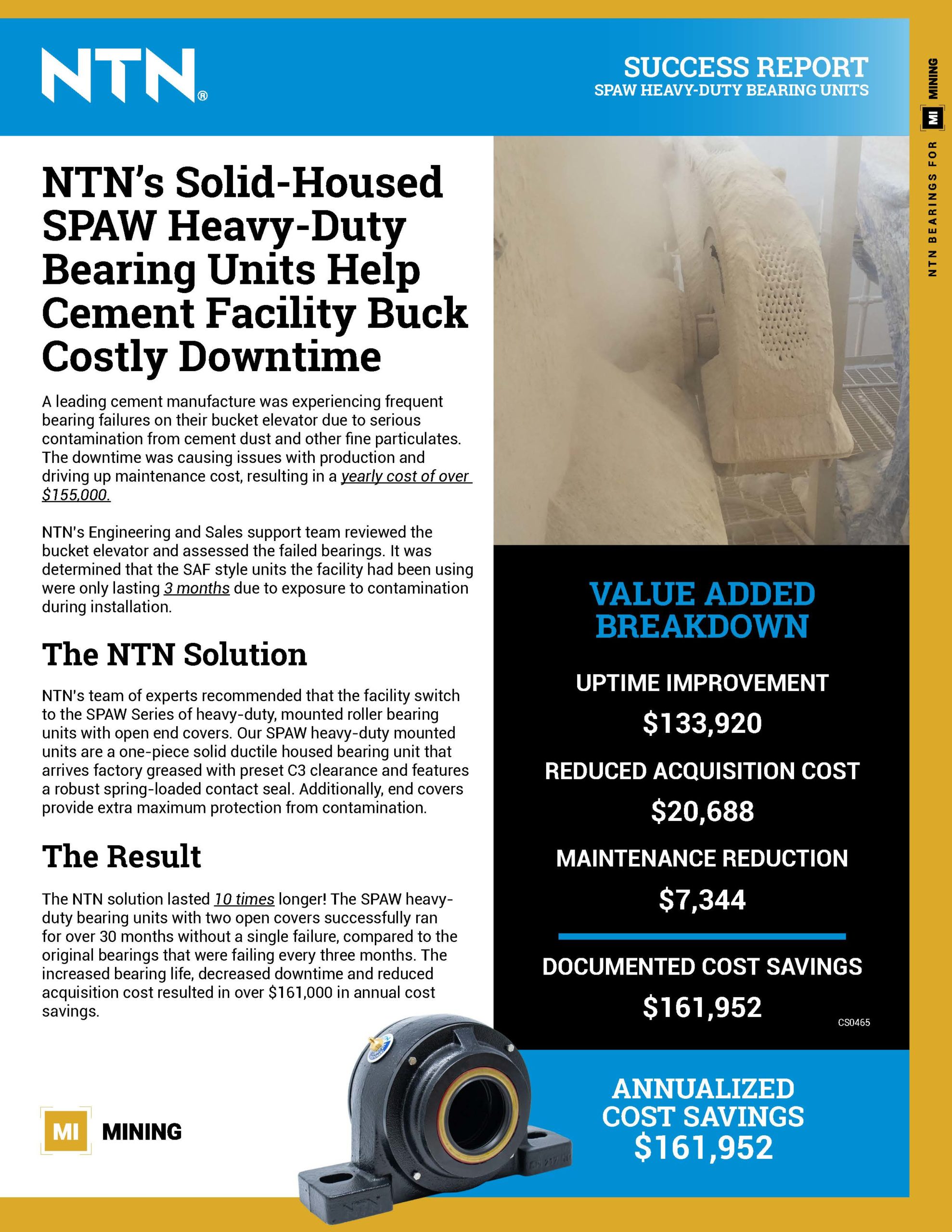

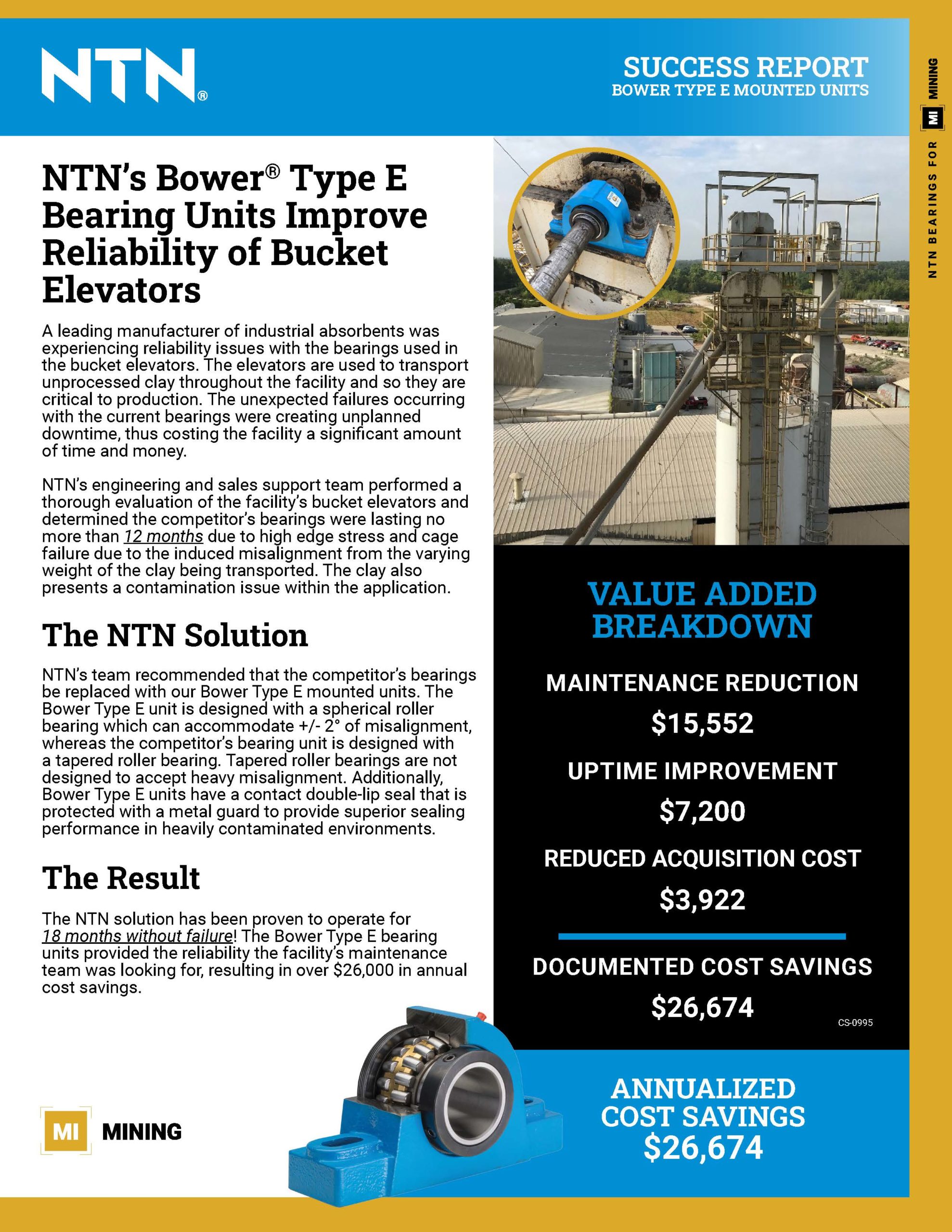

Nothing punishes bearings quite like mining & aggregate equipment. The extreme loads, grit, vibration and shocks require specialized bearing designs that can reduce the risk of unplanned failure, extend your service intervals and improve in-operation performance. NTN has decades of experience, specifically for the handling of heavy materials and other quarry-specific applications.

Mining & Aggregate Bearings

Rock-Solid Bearing Products That Meet the Rigorous Requirements of the Industry

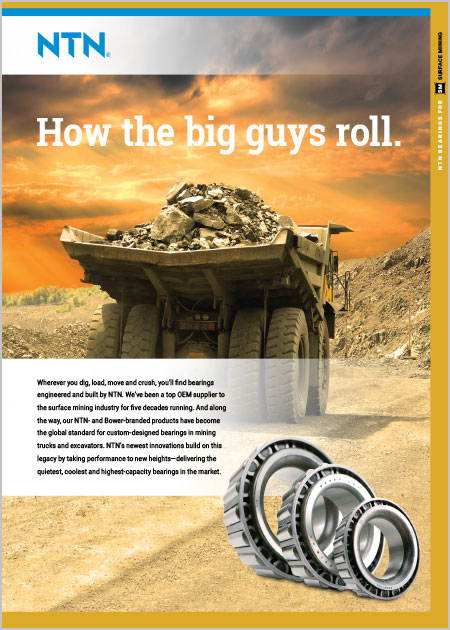

TRUSTED BY OEMS WORLDWIDE

NTN has been a top OEM supplier to the industry for five decades running. Along the way, our products have become the global standard for custom-designed bearings in mining equipment. NTN is at the forefront of bearing innovation, applying our deep industry knowledge to design and engineer solutions that make a real difference to your operation’s productivity— while reducing unplanned failures and overall equipment lifecycle costs.

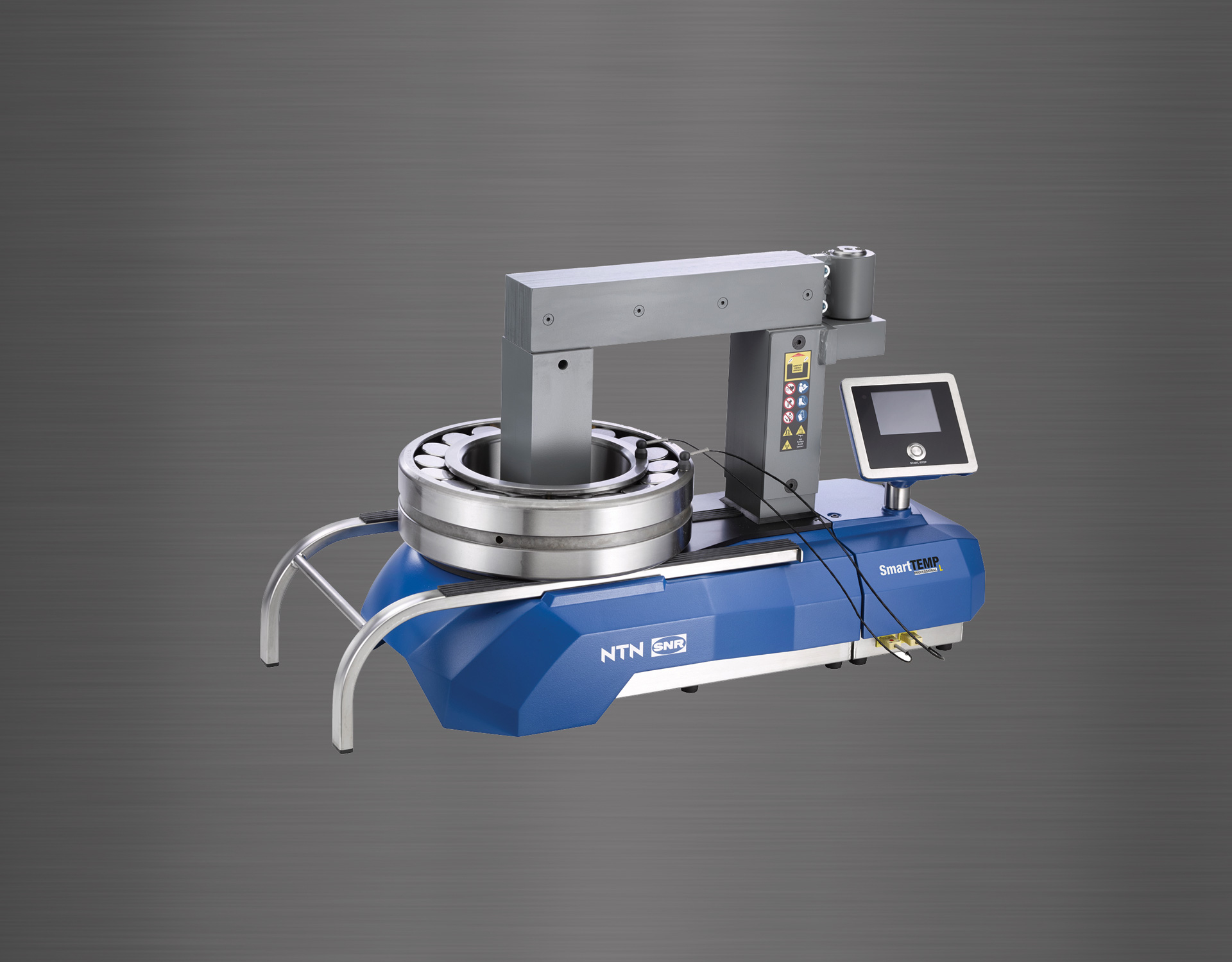

THE FOREFRONT OF INNOVATION

Our deep understanding of your unique challenges gives us the insight to know it takes specialized bearings to ride out the punishment that mining equipment dishes out—punishment that most bearings aren’t made to handle. Good news: NTN bearings aren’t made like most bearings. They are built smarter to work harder. That’s because NTN is at the forefront of bearing innovation, applying our deep industry knowledge to design and engineer solutions that make a real difference to your quarry’s productivity, while reducing unplanned failures and overall equipment lifecycle costs.

RELATED PRODUCTS

NTN offers a wide and deep breadth of bearing products to suit your specific needs. If you have not found the exact product you are looking for, please refer to some of these suggested products.

DELIVERING NTN

SOLUTIONS

AUTHORIZED DISTRIBUTOR SEARCH

NTN has dozens of manufacturing plants and distribution centers throughout the Americas, to keep our distribution channels fully stocked. Use our distributor locator tool to find a distributor close to you.

BEARING FINDER

Are you looking for a specific size of bearing? Do you have an NTN or other part number to look up? Do you need a CAD file or technical specifications? Find and download the bearing information you need with NTN’s robust online product catalog tool.

CONTACT US