industry

Food and Beverage

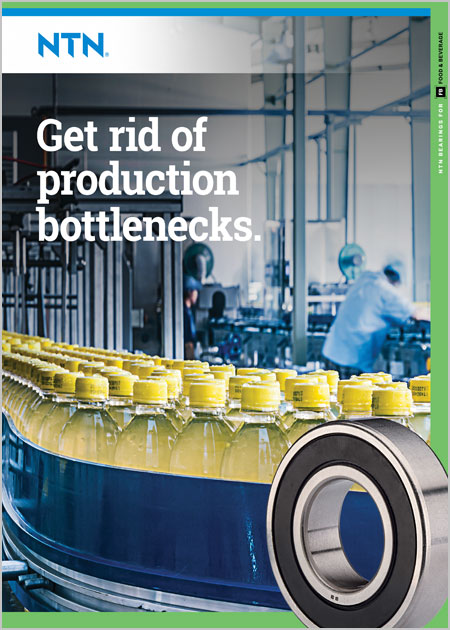

Day in and day out, crucial components of your food and beverage operation are subjected to high vibration, corrosion, contamination, harsh chemicals, grease washout and heavy, uneven bearings loads; issues that can slow your plant’s productivity to a trickle. NTN’s precision engineered beverage and food grade bearings keep you running efficiently and effectively.

Beverage and Food Grade Bearings

Providing the durability and flexibility required for food-grade environments

THE BEST BEARING SOLUTIONS FOR FOOD & BEVERAGE INDUSTRY

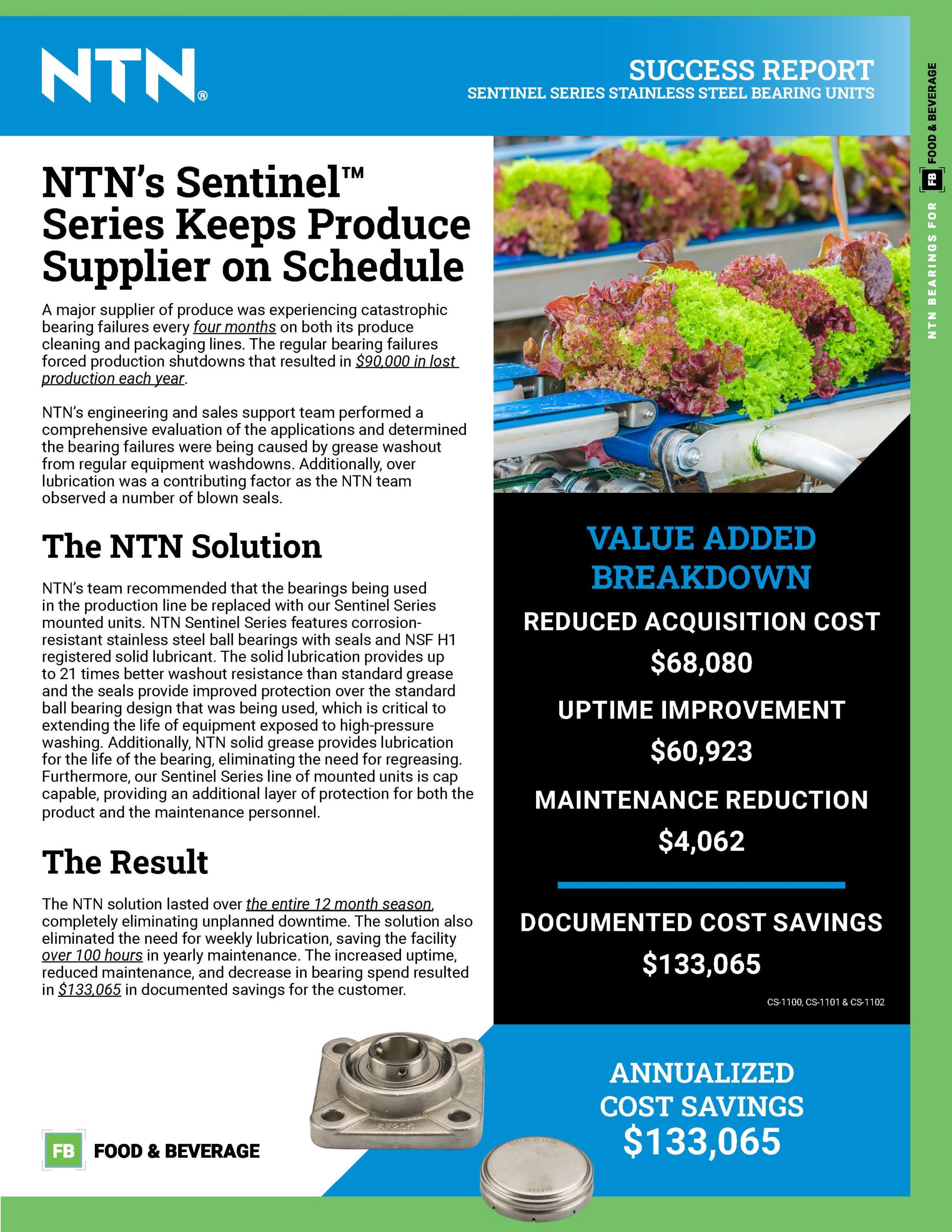

NTN Sentinel Series bearings were developed specifically for the harsh conditions of the food and beverage industry. With available products ranging from deep groove ball bearings, bearing inserts and mounted units available in numerous combinations of housings, protective covers, grease and sealing options, NTN provides a family of food and beverage market solutions to improve your overall equipment effectiveness, while increasing production and profits.

Visit the Sentinel Series section on our Mounted Units and Pillow Blocks page to learn more.

RELATED PRODUCTS

NTN offers a wide and deep breadth of bearing products to suit your specific needs. If you have not found the exact product you are looking for, please refer to some of these suggested products.

DELIVERING NTN

SOLUTIONS

AUTHORIZED DISTRIBUTOR SEARCH

NTN has dozens of manufacturing plants and distribution centers throughout the Americas, to keep our distribution channels fully stocked. Use our distributor locator tool to find a distributor close to you.

BEARING FINDER

Are you looking for a specific size of bearing? Do you have an NTN or other part number to look up? Do you need a CAD file or technical specifications? Find and download the bearing information you need with NTN’s robust online product catalog tool.

CONTACT US